Enhanced dimensional stability using alloys

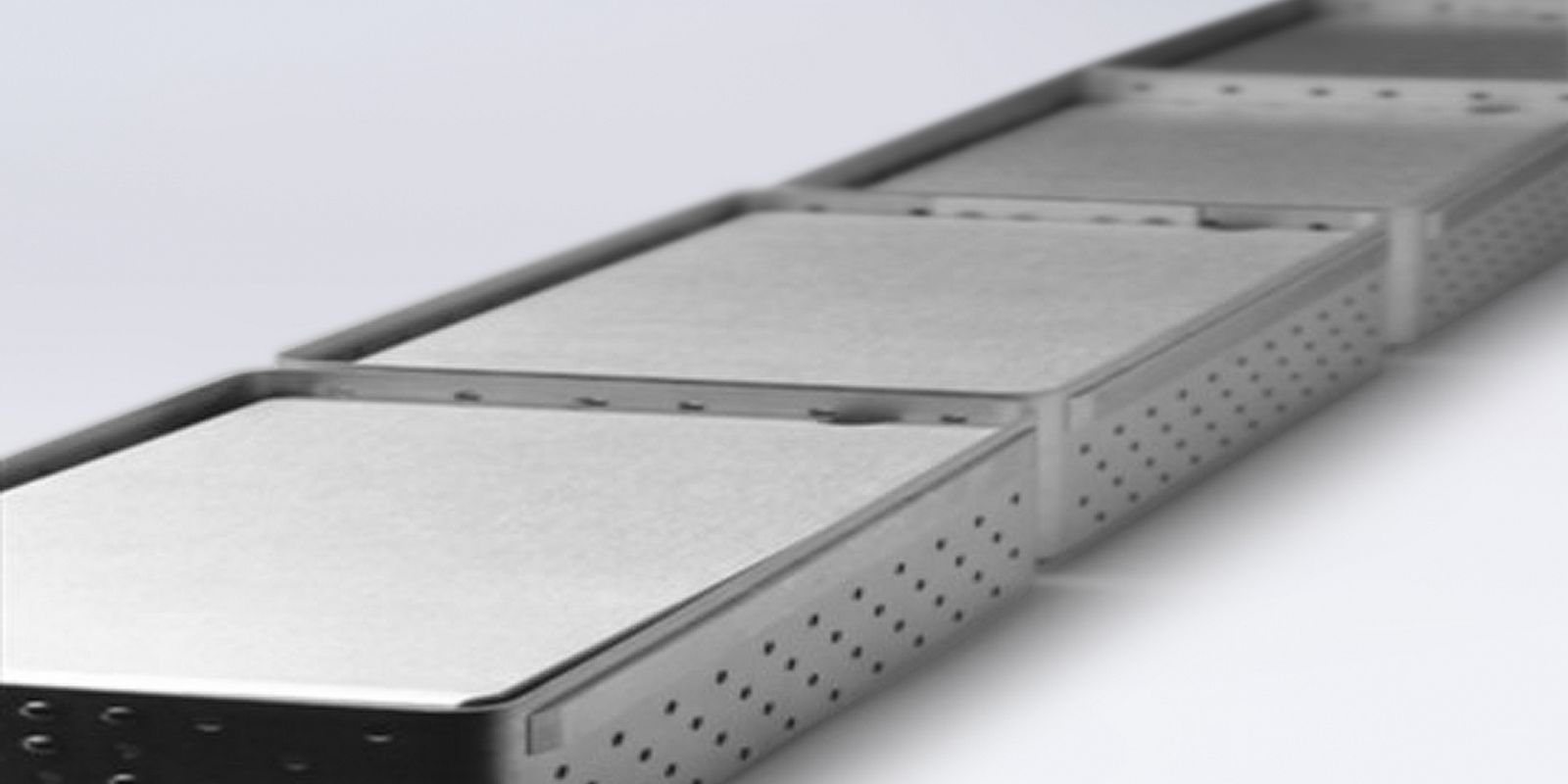

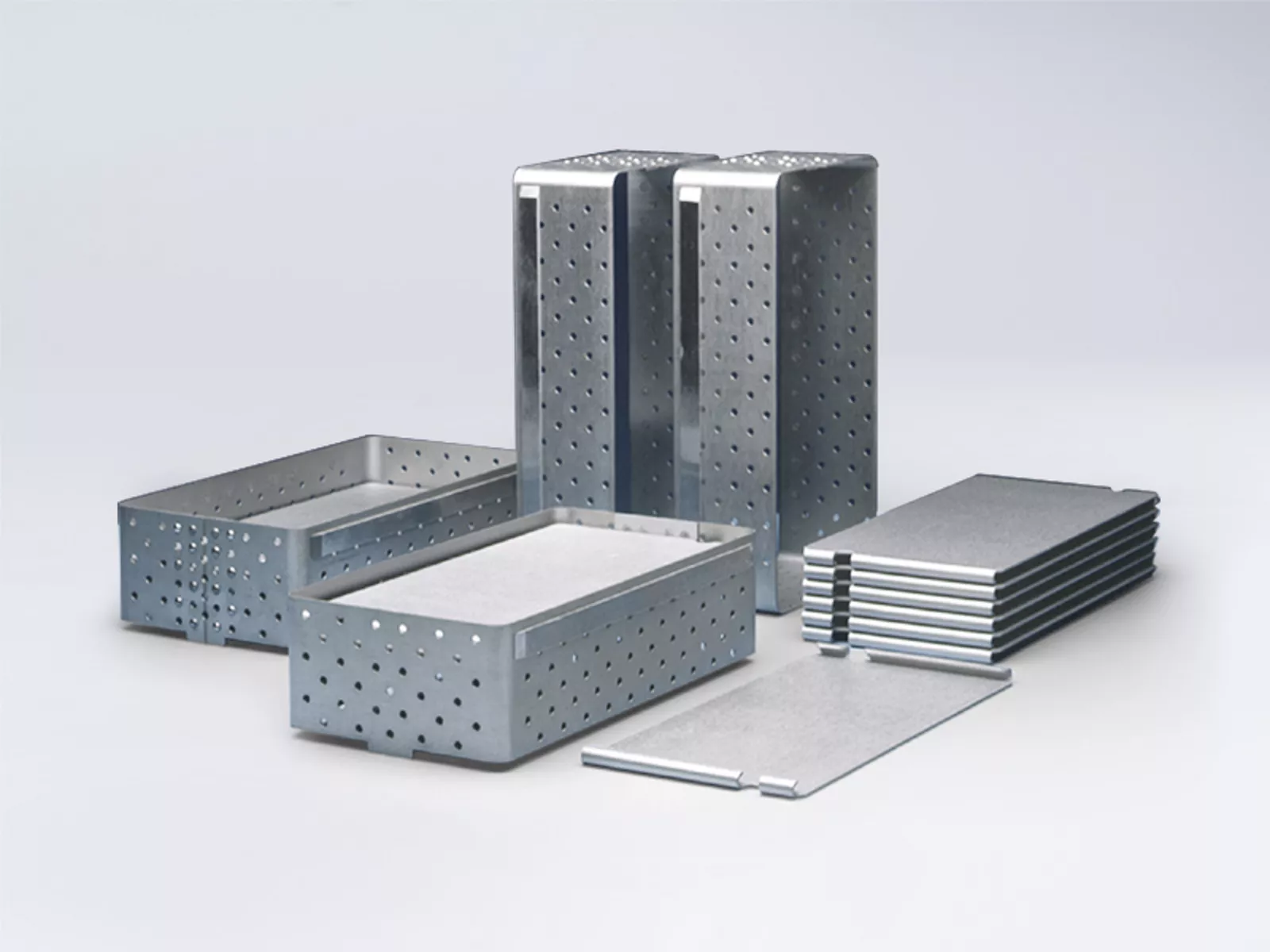

Using suitable alloys and optimized production processes, we can improve the properties of molybdenum. If you have special requirements regarding the dimensional stability of our combustion and sintering boats, then we recommend molybdenum-lanthanum and TZM.

Molybdenum-lanthanum

To achieve a particularly high level of ductility and creep resistance, we dope pure molybdenum with small quantities of La2O3. The stabilized microstructure and modified recrystallization behavior prevent the premature embrittlement and fracture of our furnace components.

Advantages of ML compared to pure molybdenum:

- Higher recrystallization temperature

- Elongated grain structure for higher ductility

- Greater creep resistance

TZM

We strengthen the microstructure of pure molybdenum with titanium and zirconium to produce particularly robust materials. A Mo-Ti solid solution and Ti-Zr carbides ensure optimal strengths at temperatures up to 1400°C.

Advantages of TZM compared to pure molybdenum:

- Better creep resistance

- Higher recrystallization temperature

- Greater high-temperature stability