From fixing systems up to machine controls

The following categories show a selection of accessory components developed by us which are ideal for use with CNC dividing heads.

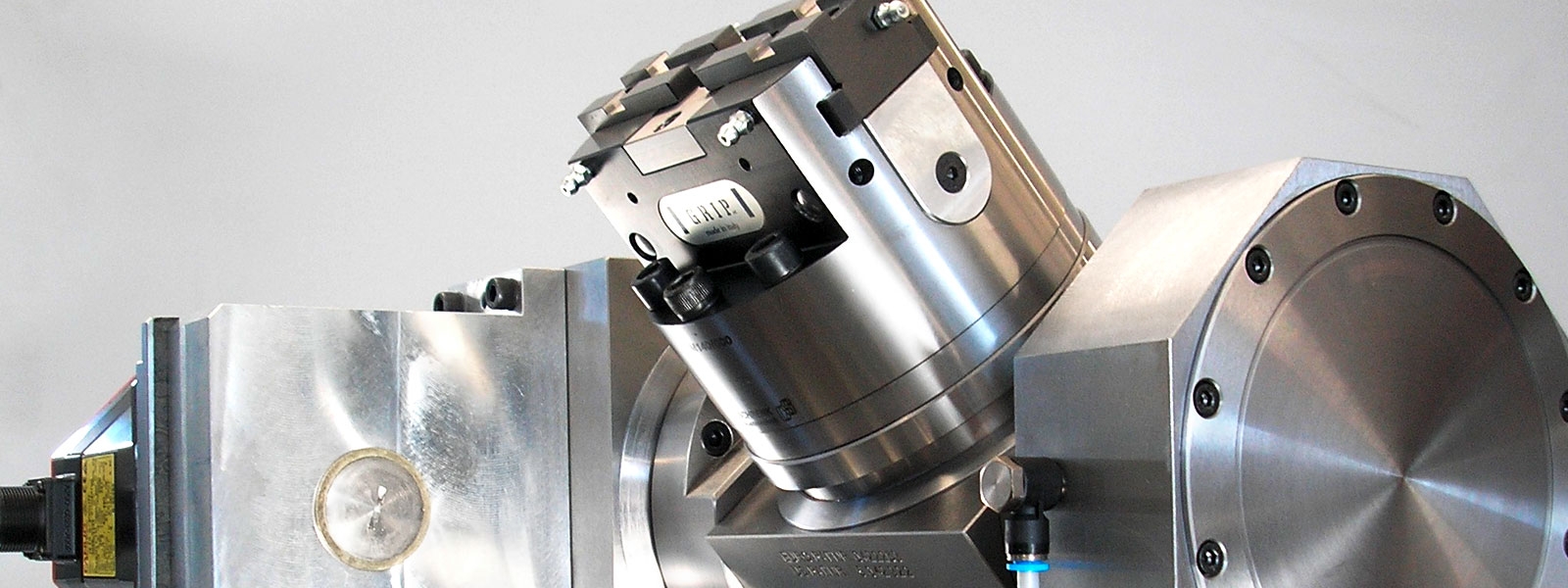

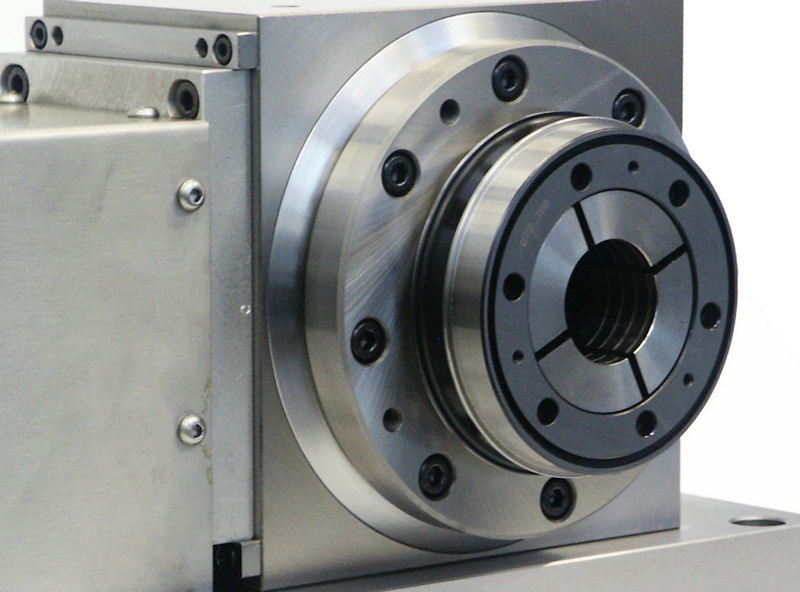

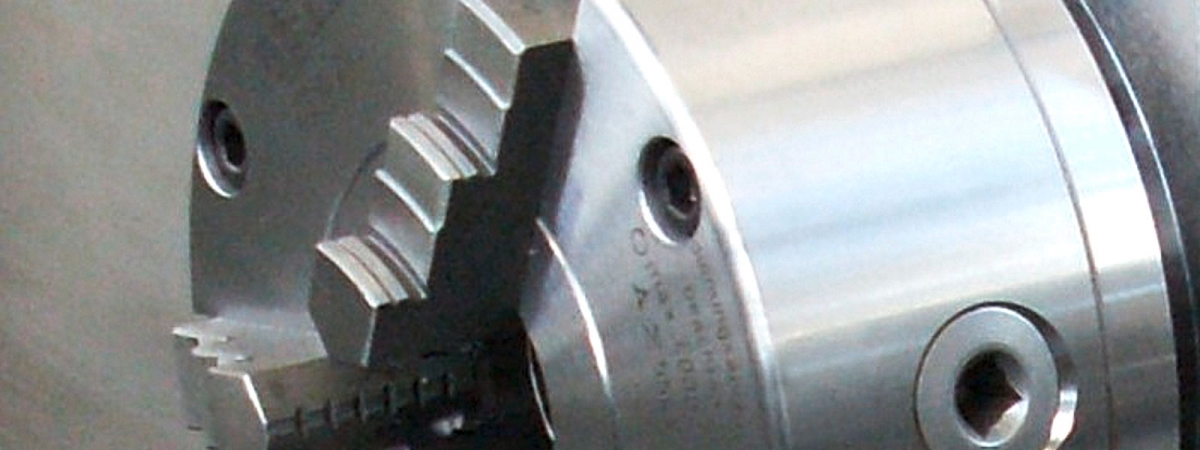

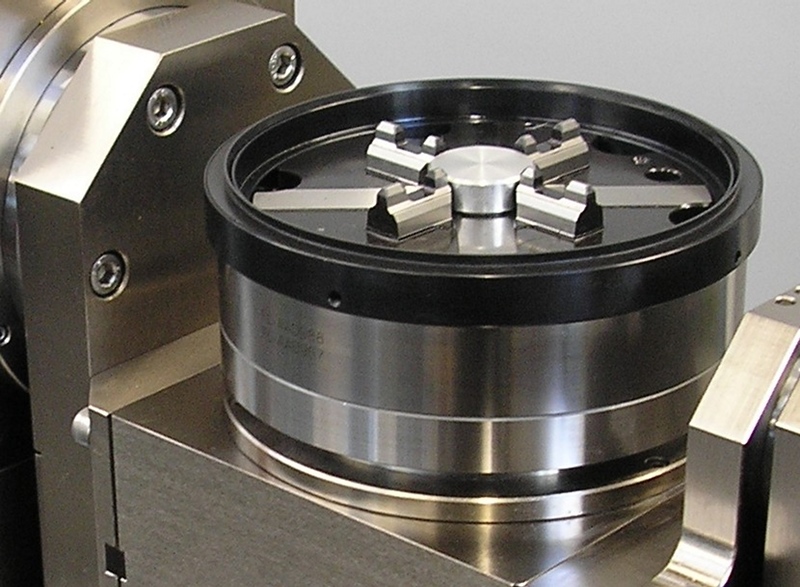

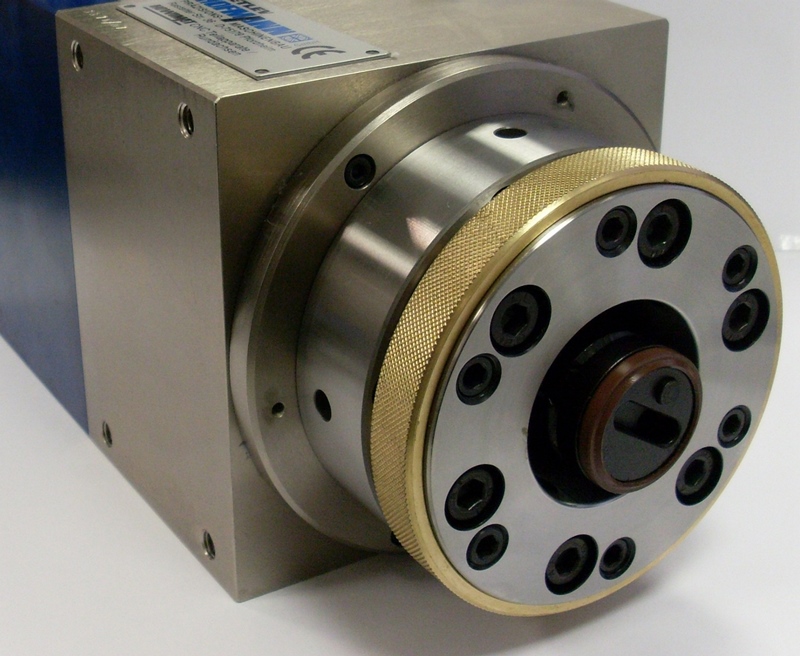

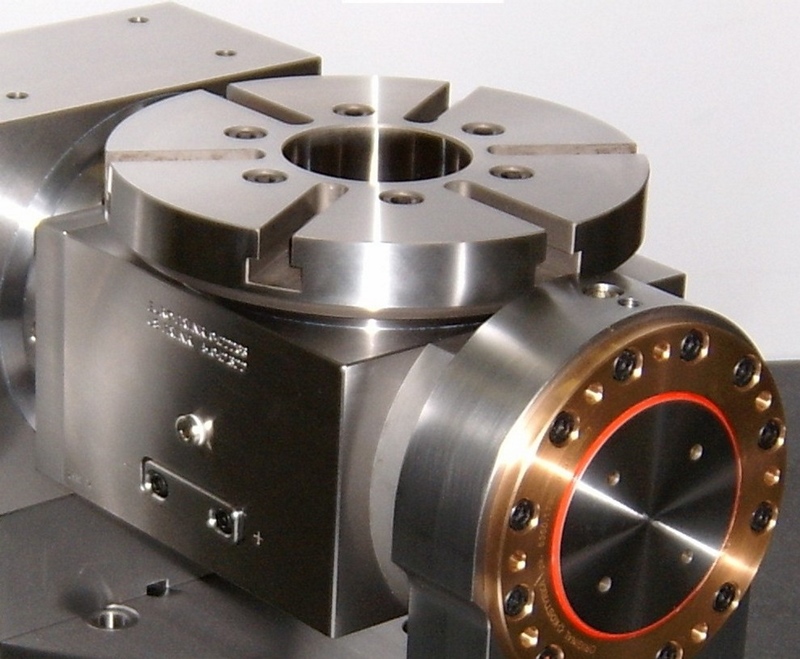

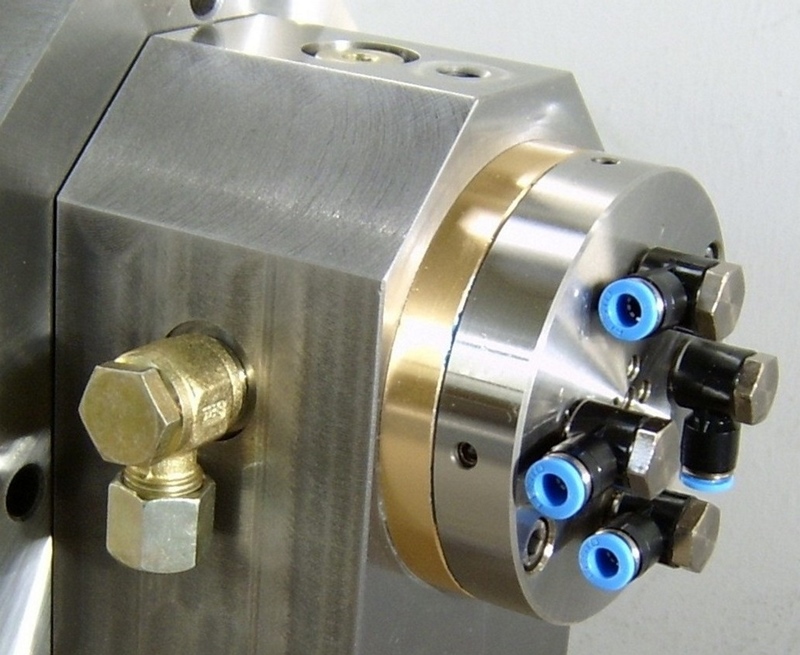

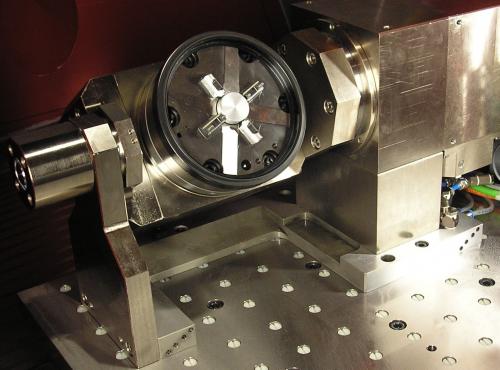

For the purpose of efficient workpiece clamping we have compiled an overview of different clamping systems. In additional to conventional collet attachments and taper type holders, the collection also includes jaw chucks and various pallet chucking systems and zero point clamping systems.

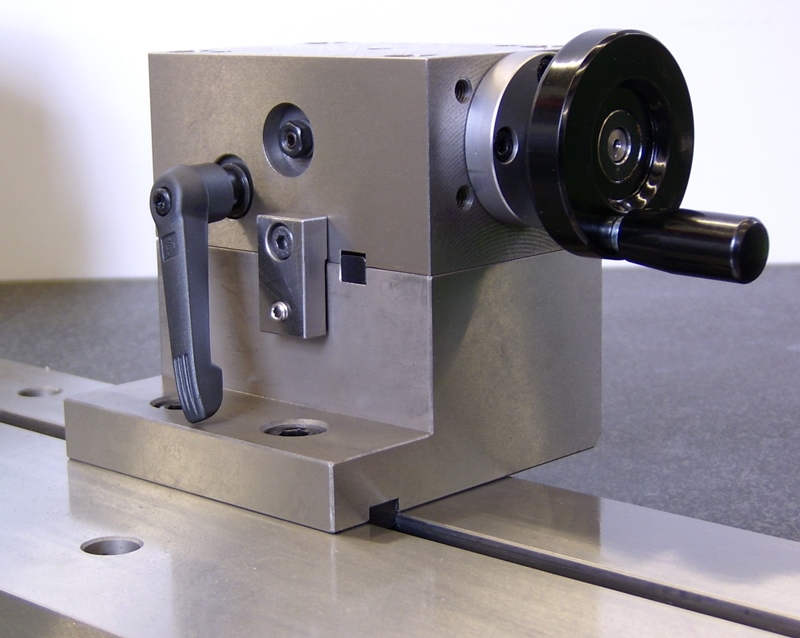

“Everything for your dividing head” presents a short overview of base plates, thrust bearings, swinging bridges and tailstocks which in the event of an order can be adapted to your requirements.

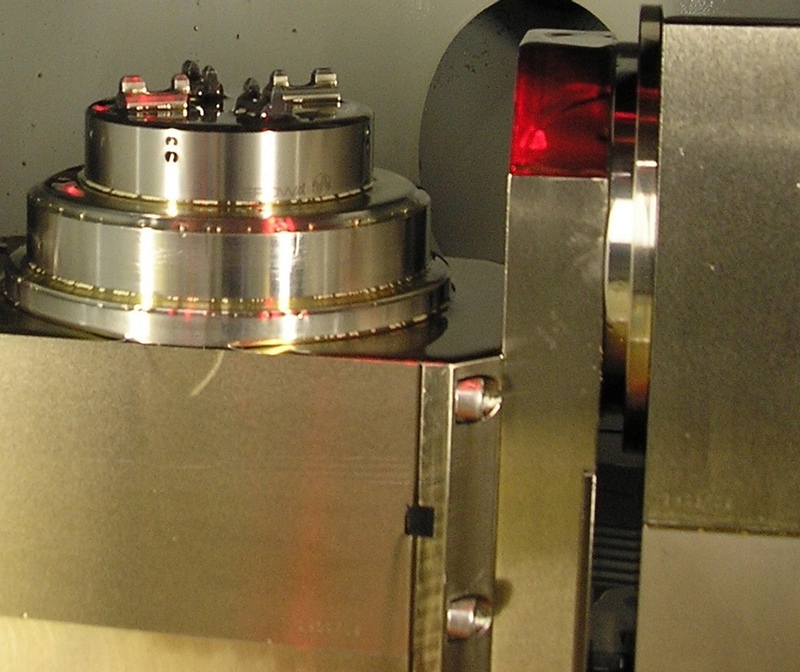

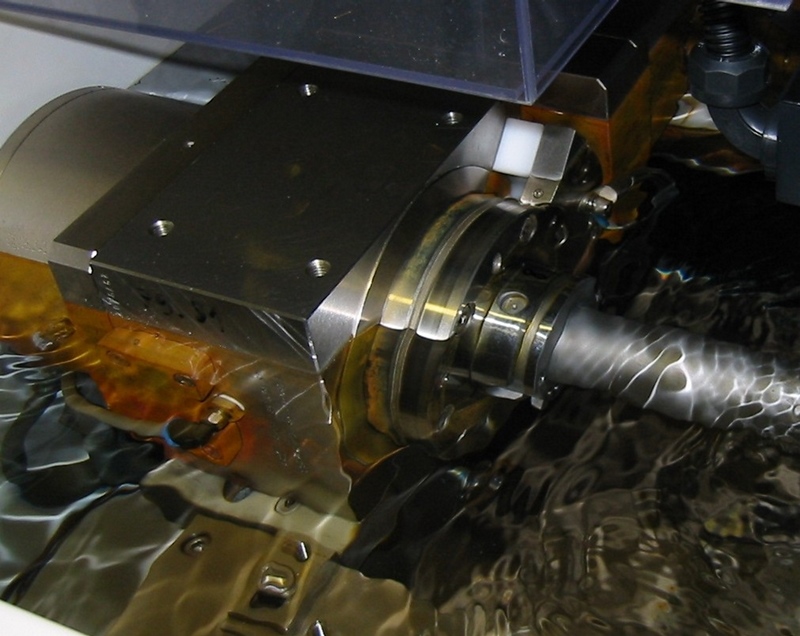

For special requirements we can offer you dividing heads in stainless steel (completely sealed, IP68 version) which are suitable for use with EDM machines.

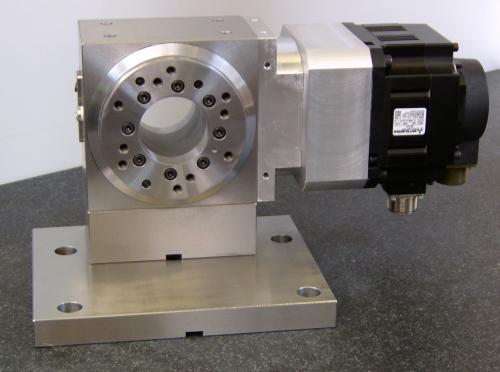

Under the category “Control and electrical connections” there is an overview of drive motors and drive packages which in the event of an order can be specially selected and made ready as required for use in your machine control system.

Perhaps you are still looking for the right accessories for your CNC dividing head. Please ask us for more information. We are looking forward to your enquiries and will surely be able to find the right solution for you.

Work-holding devices and systems

Around the dividing head

For special requirements

… much more on request – according to customers requirement!

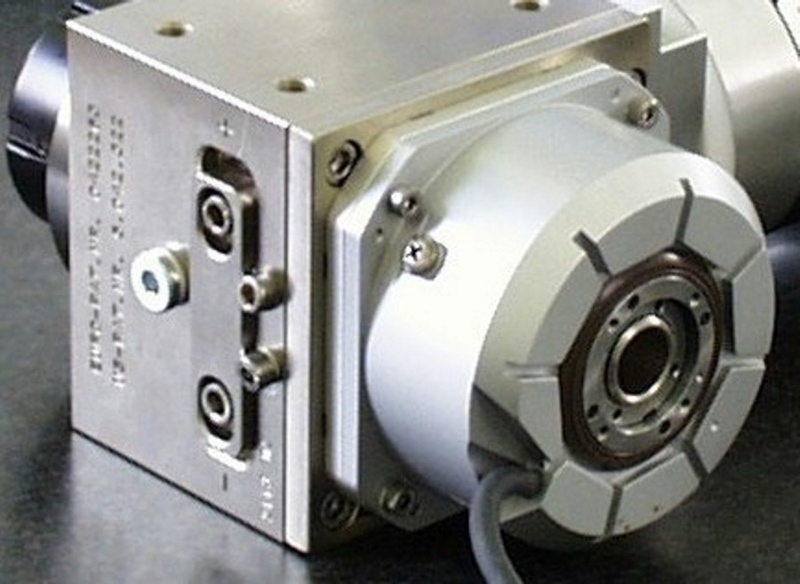

Control systems and electrics

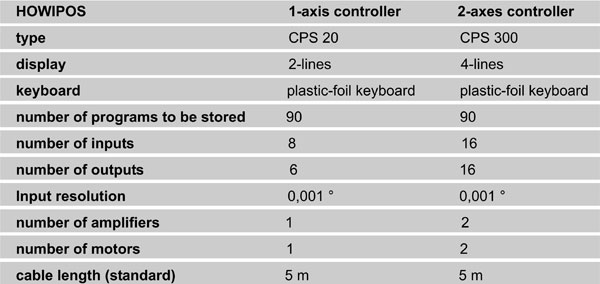

Operation with a separate dividing head control system and M-function

Our control system type HOWIPOS 1/AC is a modern Microprocessor CNC-positioning control. Positioning controller, control system and operating panel are all mounted in a compact console. The control is easy and comfortable to use with and easy, menu-guided programming system. The illuminated LCD-display shows all input data and indications in clear text. A special program has been developed for the use of the HOWIPOS control with rotary-tables and dividing heads. The control system is mounted in a table-top housing and connected with the dividing head – ready to use. The activation of the control system, by means of an M-signal from the machine is already prepared.

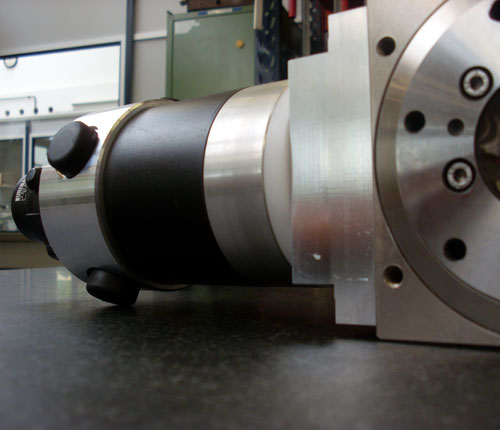

Control by means of the machine tool controller e.g. 4th or 4th / 5th axis of a machine tool control system

(Not valid for TMI type units) The motors of all popular motor-manufacturers are suitable to be built on to our units e.g. and others (please specify)Servomotor according to customers requirements, to suit customers own control system

Appropriate drive packages to suit machine control system