Howimat gear-type units

The patented recirculating ball gear system is the heart of the rotary table and is implemented in each CNC dividing head of our gear drive series

The gear drive:

- enables precise positioning of the spindle

- can accept high torque forces

- has easy backlash adjustment

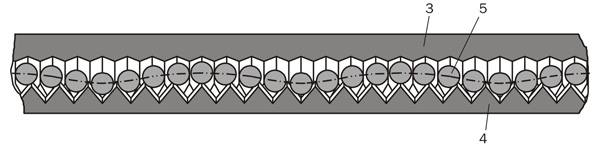

Patented recirculating ball gear system

Technical features:

- Highest precision due to patented recirculating ball gear system

- No additional clamping of the dividing head spindle required

- High positioning speed

- Optimal torsion stiffness

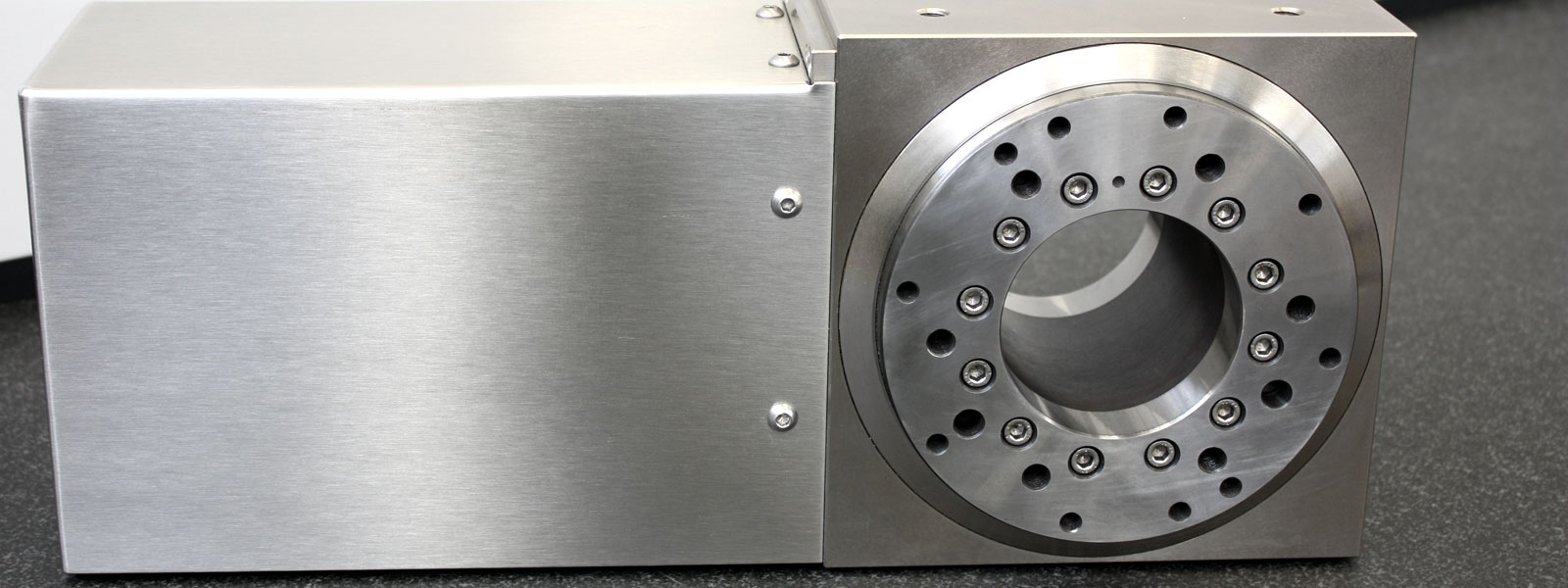

- Very compact design

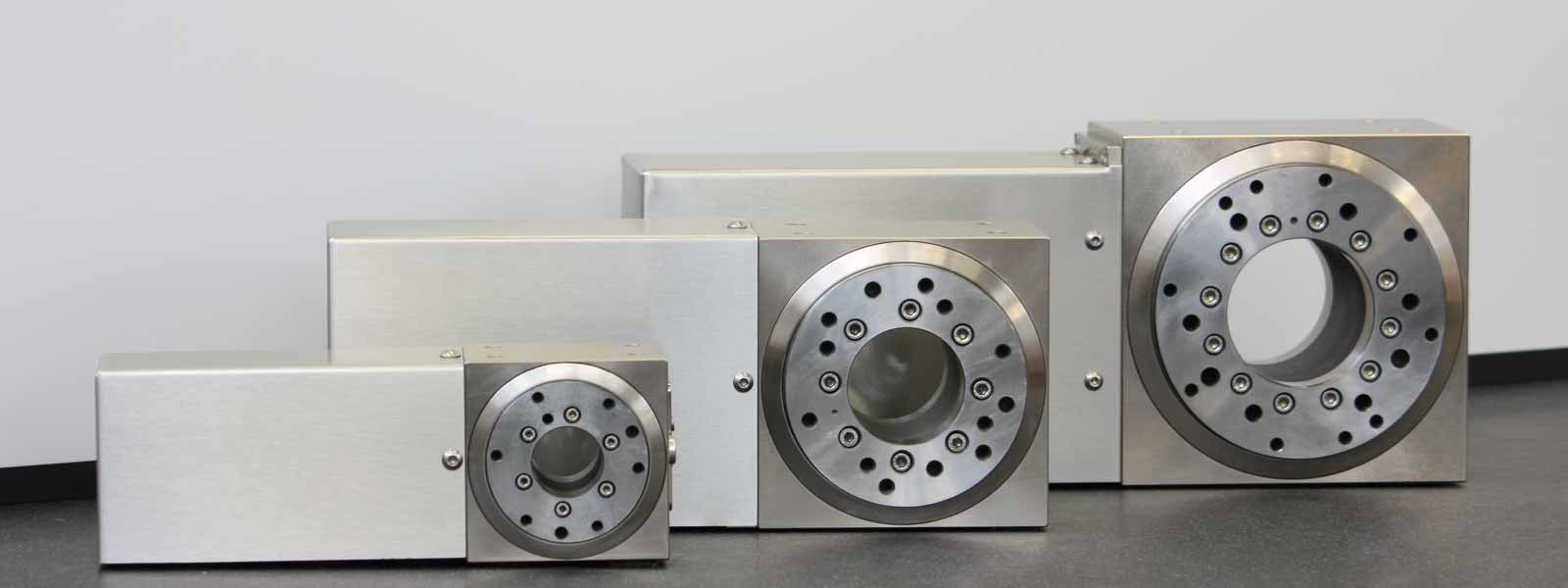

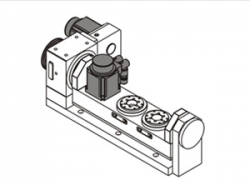

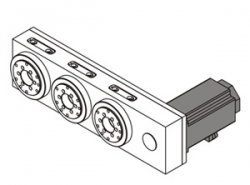

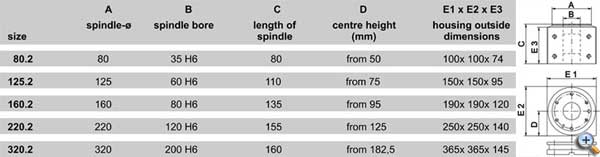

- 5 sizes available

- Big spindle bore

- Wide range of additional equipment available

- Suitable for diversified applications

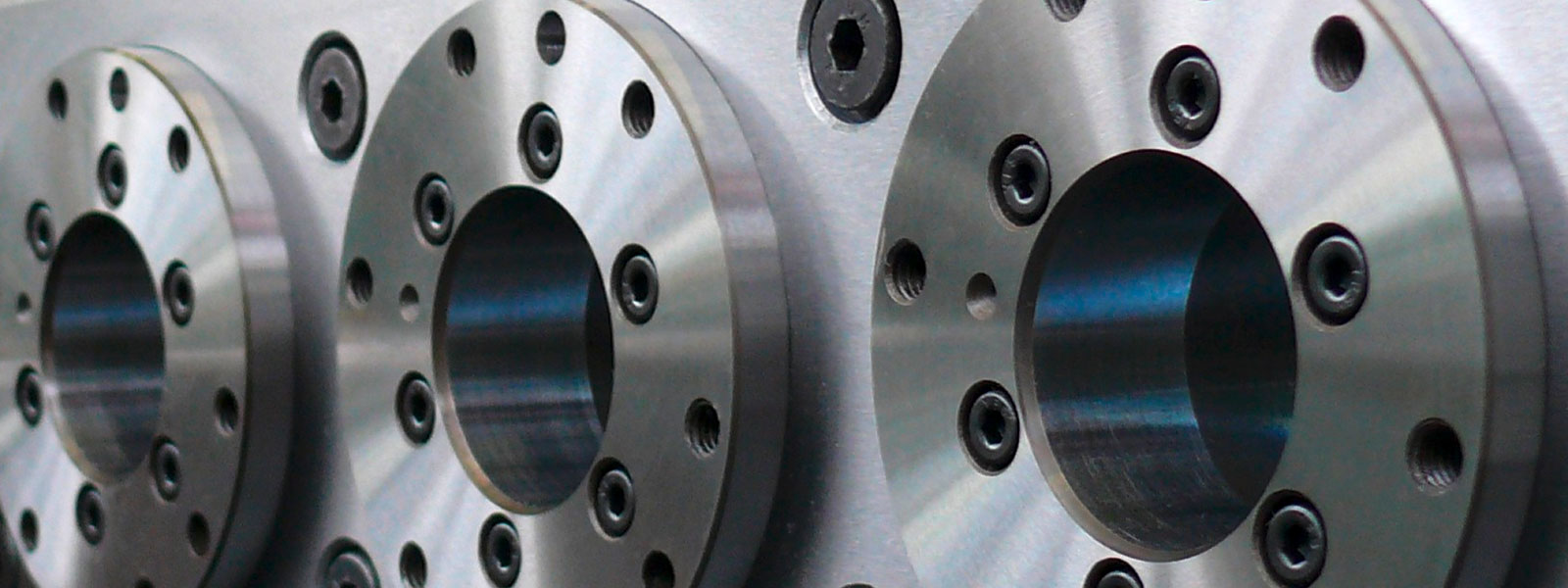

Our axes consist of

- Heavy duty, high precision axial-radial roller bearings

- Patented recirculating ball gear system

- Auxiliary transmission (bevel gear drive or belt-drive system)

- Completely sealed and precision-ground housing

Functional description

The balls (5) are actuated by a circular cam to lift them up and back down into a fixed tooth disc (4). The second tooth disc (3) accepts the balls, but has a different number of teeth.

In contrast to contemporary gear drives, torque and overload are generally transmitted by two gear teeth, the HOWIMAT precision recirculating ball drive system has a large number of balls engaged in the transmission.

Nearly 40% of the balls on the gear circumference are supporting the transmission. This generates a very high stiffness in torsion of the gear, which is irreversible. Therefore most applications don’t require any additional clamping system, assuming the proper sized unit is selected.

The entire gearing area is used for transmission even for small angular pitches and therefore the precision of the recirculating ball gear is ensured for an extended period of time, even if a load is concentrated in the same point for an extended period of time.

Our system provides a major benefit over conventional gear systems in production environments, as conventional systems will wear locally on certain position areas of the gear, something which is unavoidable. Using our system we completely remove this problem which has been the major flaw of existing systems since their inception.

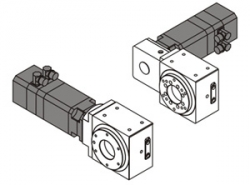

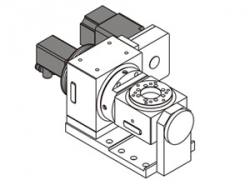

Design variations

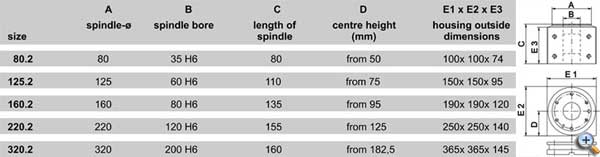

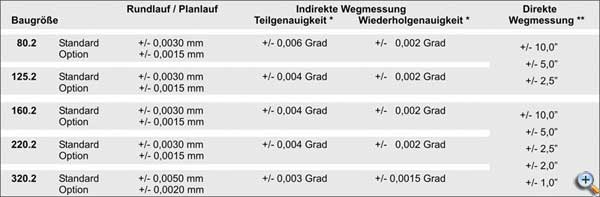

Technical data

Weight, speed …

* With HOWIMAT CNC-dividing heads no additional clamping is required.

If an increased mass moment of inertia could be created, due to fixture or work-piece design, please contact us.

** reduction ratio may vary for Z-version (additional tooth-belt drive)

*** higher rpm in Z-version

Subject to change without prior notice!

* During simultaneous machining, the load should not be bigger than 50% of the maximum, due to the regulating performance of the motor.

** The shown driving torque is the maximum load. The possible driving torque depends on the chosen motor (if motor type is known, figures can be given upon request)

*** The shown tangential moment is the maximum permissible load with the corresponding elastic deformation (when machining at the load limits, please contact us. Additional clamping systems upon request)

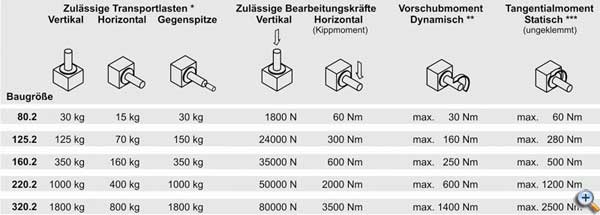

Load details and accuracies

* When positioned from one side 0,001 degr. = 3.6 arc sec.

For higher accuracies direct measuring systems are available;

e.g. Heidenhain ECN223 (+/- 10”); RCN226 (+/- 5”); RON285 (+/- 5”); RCN729 (+/- 2”) etc.

– other built-in measuring systems upon request

– increased bearing accuracy available as an option

Technical details are subject to change without prior notice.