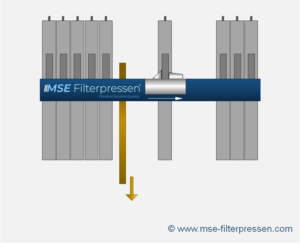

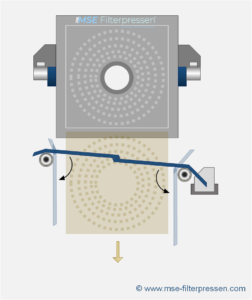

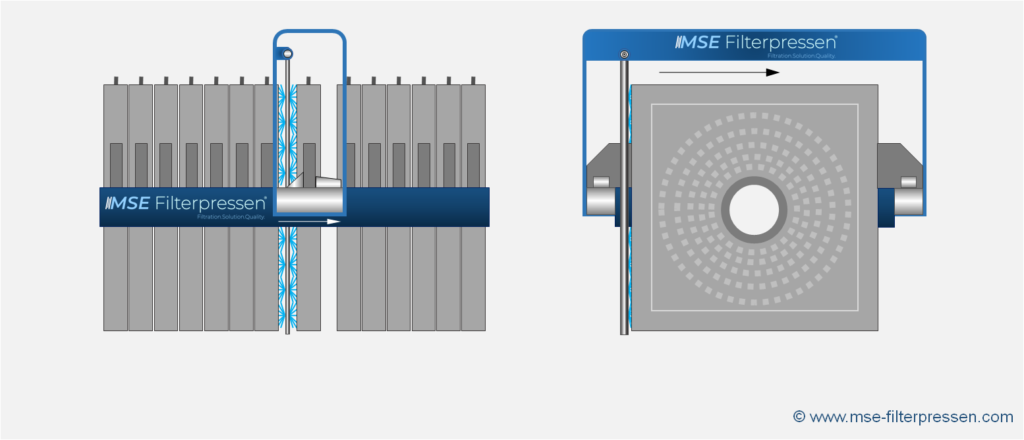

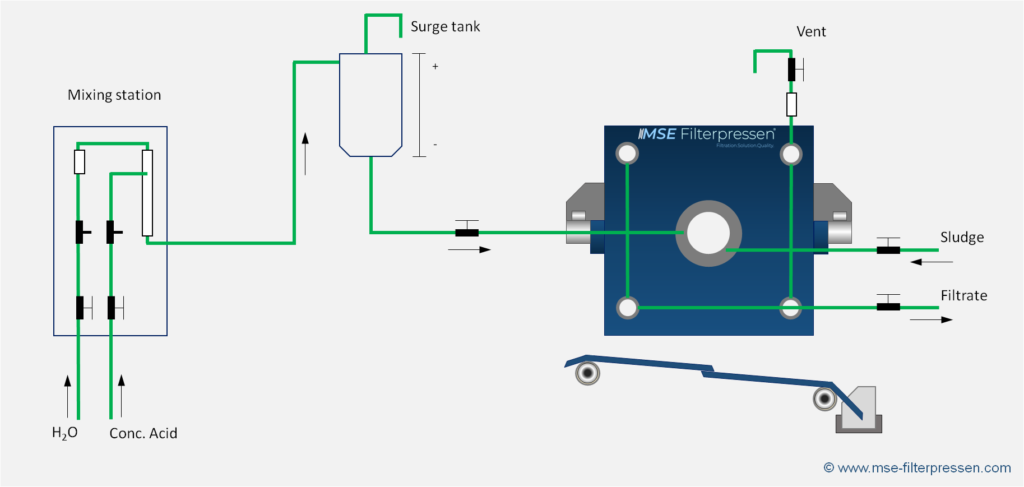

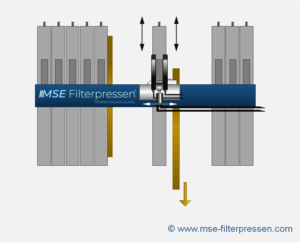

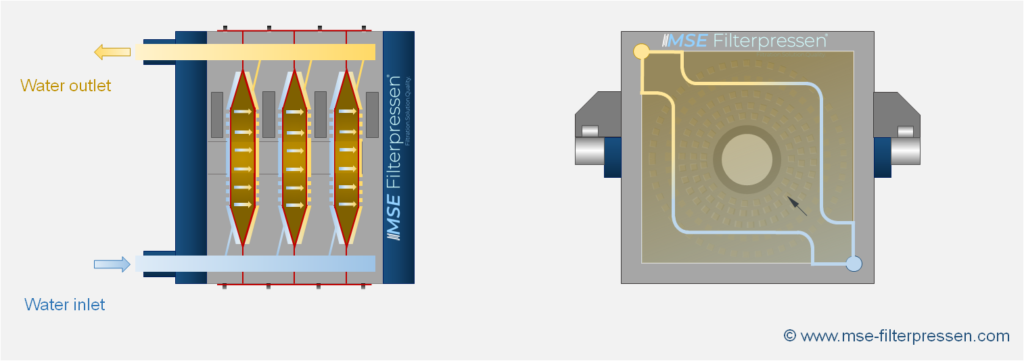

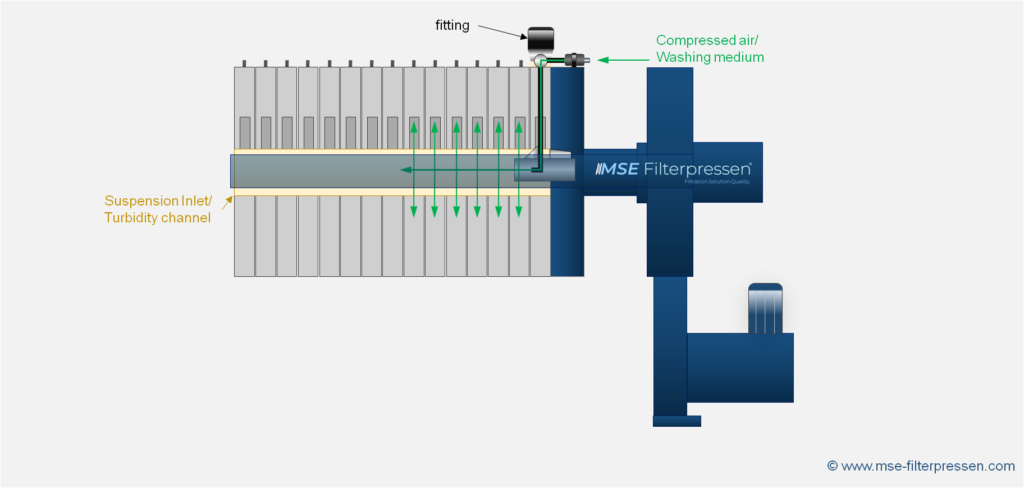

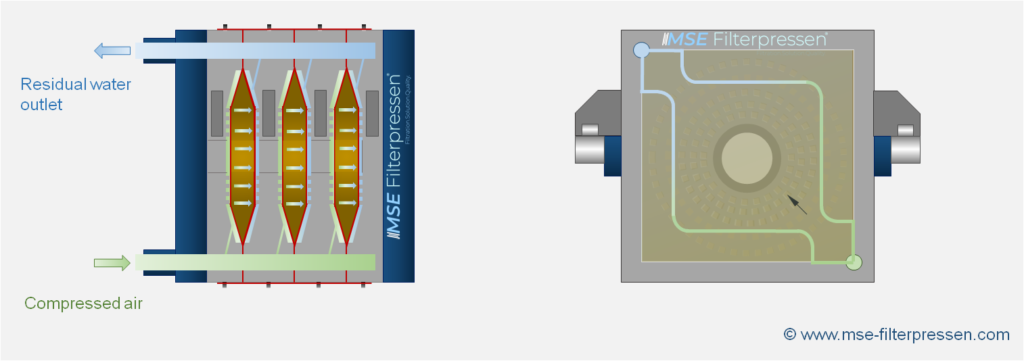

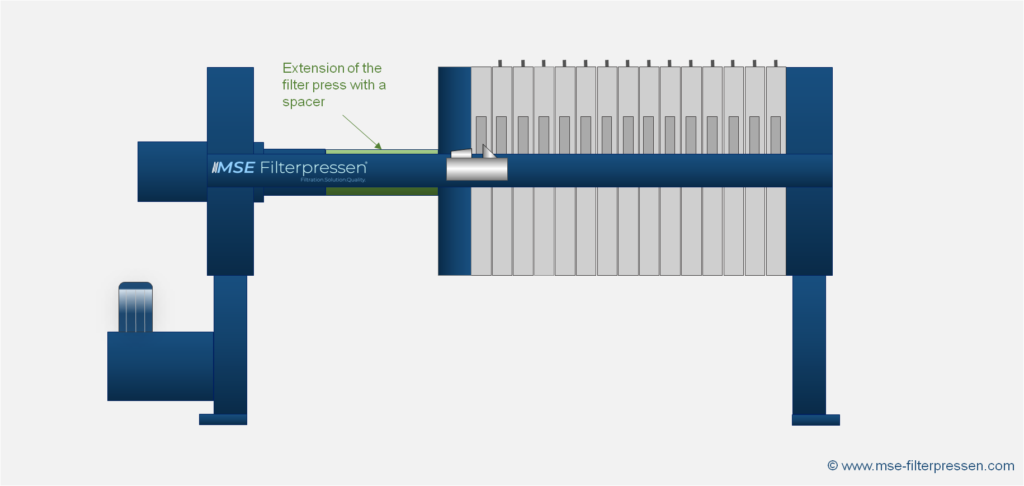

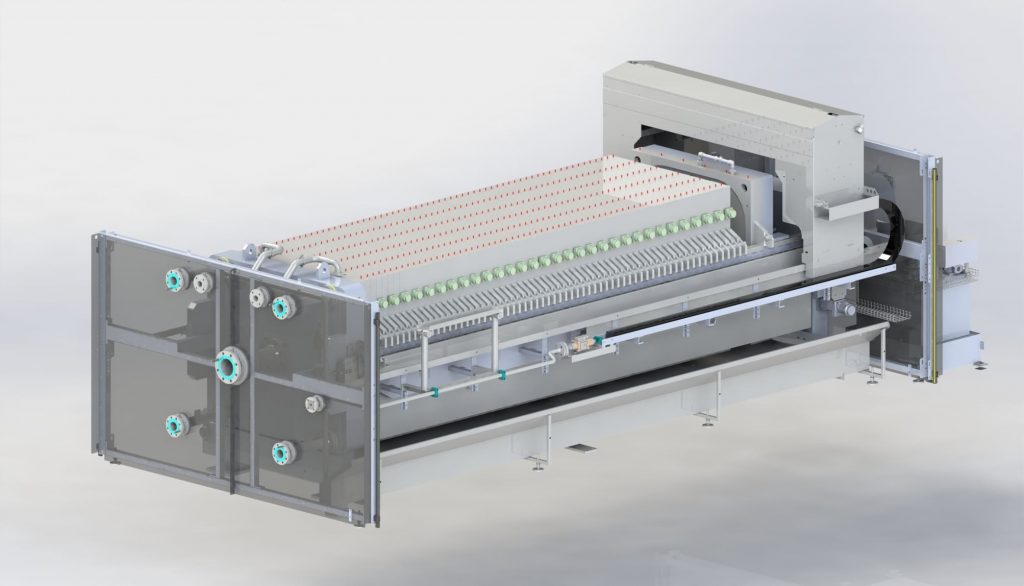

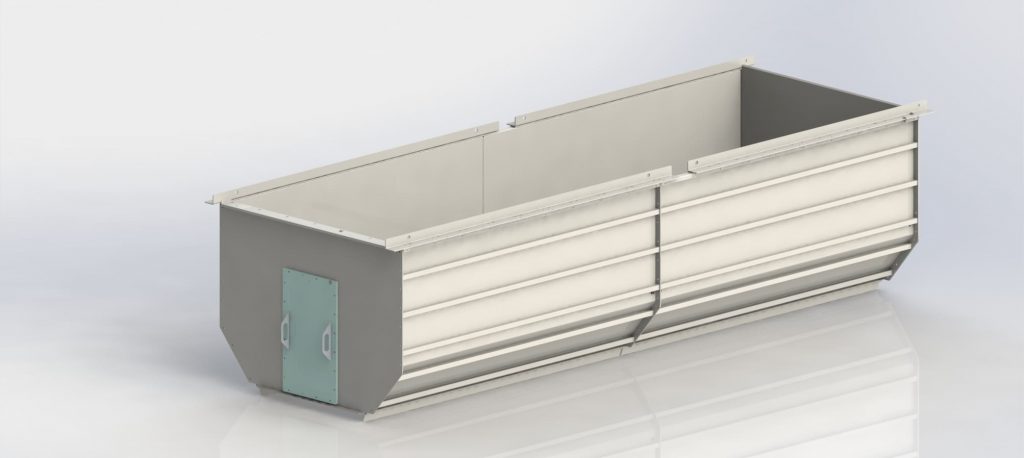

Due to its excellent filtration results, the membrane filter press has proven itself in a number of applications, e.g. in mining, chemical or pharmaceutical industries. In order to meet the different requirements of industry and municipalities, MSE membrane filter presses are designed in modular design analogous to chamber filter presses. The solid and heavy-duty steel filter press frame, which consists of the following main components, forms the basis: Feeding stands with filtrate outlet (head piece), hydraulic stands with locking cylinder (pressure piece), cross beam and side rails on which the individual membrane filter plates are arranged including filter cloths. The plate package consists of uniform membrane plates (optionally a mix of chamber membrane filter plates is also possible) with a cutout of 15-50 mm to accommodate the puncture-proof filter cake. The standard membrane material used is polypropylene (PP), synthetic rubber (e.g. NBR, EPDM) or thermoplastic elastomer (TPE). Special materials such as PVDF are also available. Membrane filter presses have a great influence on the dryness of the solid by using membrane technology in the filter plates. Compared to conventional filtration processes, it achieves the lowest residual moisture values in the filter cake. This makes the membrane filter press a powerful and the most widely used system.

MEMBRANE TECHNOLOGY AS A SOLUTION – IF TIME AND DEGREE OF DEWATERING ARE CRUCIAL

Depending on the degree of dewatering, different dry matter contents (dry matter content – percentage by weight of dry material in the filter cake) can be achieved in the filter cake by squeezing with membrane plates. The range of achievable dry matter contents extends from 30 to over 80 percent. In the standard version, squeezing is carried out on both sides. Depending on the medium to be filtered, there is the option of only using membrane technology for every second filter plate. The combination of membrane filter plates and chamber filter plates (mixed package) reduces the initial costs and also guarantees excellent filtration results. This type of filter press is called the chamber membrane filter press.